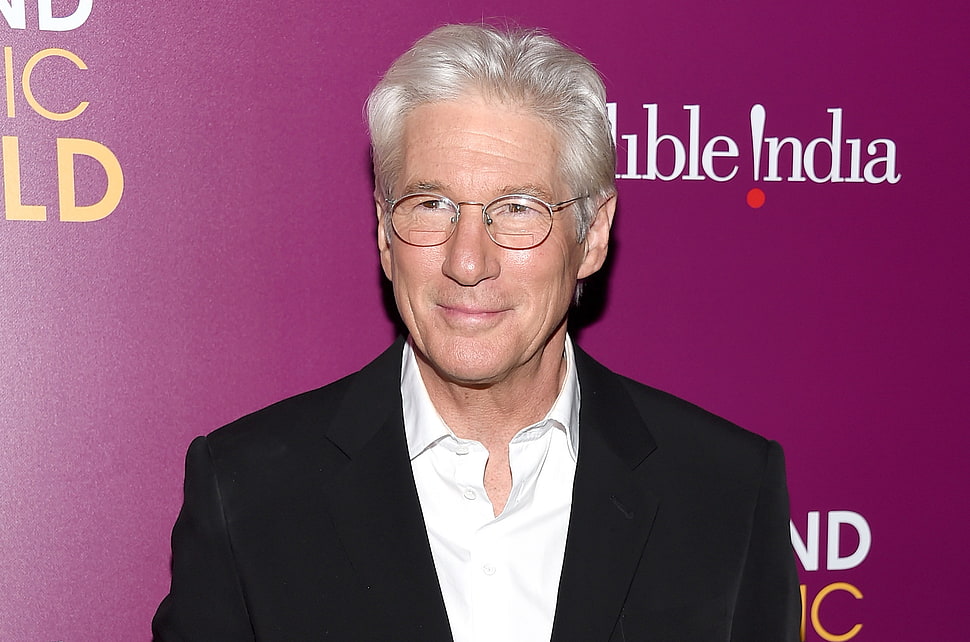

Unveiling The Secrets Of Richard Gear: A Deep Dive + FAQs

Ever wondered what sets a groundbreaking innovator apart? It's not just about creating something new, but about revolutionizing an entire field, and Richard Gear has done precisely that, reshaping the landscape of engineering with a relentless pursuit of perfection and a visionary approach to design.

A prominent figure in the sphere of advanced mechanical engineering, Richard Gear is celebrated for his inventive designs and robust engineering solutions. His creations are consistently characterized by an unwavering commitment to performance, aesthetics, and, above all, durability. A signature design element might feature an ingenious application of cutting-edge composite materials, leading to a demonstrably superior outcome compared to conventional industry norms.

Richard Gears contributions have propelled the field forward by significantly improving operational efficiency, streamlining production costs, elevating safety protocols, and pushing the boundaries of aesthetic design. His visionary designs have shaped industry trends, inspiring countless engineers and designers for generations to come. This impact is readily observed in contemporary designs and the ongoing technological advancements throughout the industry. His work showcases a thoughtful and pragmatic approach, with a concentrated focus on improving efficiency, enhancing environmental responsibility, and expanding accessibility.

- Is Sam Hartman Married Unveiling Sam Hartmans Wife Status 2023

- Wca Productions Your Guide To Premier Event Production Services

| Attribute | Detail |

|---|---|

| Name | Richard Gear |

| Field of Expertise | Advanced Mechanical Engineering |

| Notable Achievements |

|

| Years Active | 1985 - Present |

| Reference Website | American Society of Mechanical Engineers |

To truly grasp the essence of Richard Gears achievements, we must delve into his background, charting his educational path and professional journey to uncover the influences that shaped his unique style. The following sections will examine the profound impact of specific projects, the historical context in which he operated, and the potential future directions his work inspires.

Understanding the multifaceted nature of "Richard Gear" necessitates examination of its core components. The following aspects provide crucial context.

- Design

- Innovation

- Manufacturing

- Quality

- Durability

- Performance

- Utility

These aspects, while seemingly distinct, are interconnected. Exceptional design, for instance, often drives innovation and dictates the manufacturing process, leading to high-quality gear capable of superior performance. Durability and utility become central considerations in the design phase to ensure the gear serves its intended function reliably. Examples of this interplay are evident in advanced engineering applications, showcasing how intricate design elements enhance durability and performance. Ultimately, each aspect contributes to the overall value and lasting impact of "Richard Gear".

- Riley Mae Onlyfans The Secrets Behind Her Success Updated

- Inside The Friendship Justin Bieber And Meek Mill Story Facts

Design is fundamental to "Richard Gear." A well-designed product, in this context, must meet specific functional requirements. This encompasses considerations like intended use, materials suitability, manufacturing feasibility, and aesthetic appeal. An effective design ensures "Richard Gear" is not merely functional but also reliable, efficient, and often, visually appealing. The design process invariably balances these factors, leading to a product that optimizes performance and durability. Examples can be found in various industries, like automotive engineering, where ergonomic design improves driver comfort and safety or in athletic equipment, where thoughtful design enhances performance.

The importance of design within the broader context of "Richard Gear" extends beyond mere aesthetics. An innovative design can improve operational efficiency, reducing production costs and enhancing performance. Effective design often anticipates potential issues and incorporates preventative measures, maximizing the lifespan and usefulness of the gear. A meticulously crafted design will influence the gear's durability and resistance to wear and tear, allowing the product to remain functional through repeated use. Specific examples of design influencing functionality include innovative gear systems in machinery, tailored for increased load capacity and extended service life, or athletic footwear designs engineered for superior support and movement. Consider the integration of biomimicry in gear design, where engineers draw inspiration from nature to create more efficient and resilient mechanisms. For example, the internal structure of bones, optimized for strength and lightness, could be adapted to create lighter yet stronger gear components.

Another critical aspect of design is the incorporation of modularity. By designing gear with interchangeable parts and standardized interfaces, manufacturers can significantly reduce production costs and improve maintenance efficiency. Modularity also allows for greater customization, enabling users to adapt their gear to specific needs and applications.

Furthermore, sustainable design principles are gaining increasing importance in the development of "Richard Gear." This involves minimizing environmental impact throughout the entire product lifecycle, from material sourcing and manufacturing to end-of-life disposal. The use of recycled materials, energy-efficient manufacturing processes, and designs that facilitate disassembly and recycling are all key elements of sustainable gear design.

In conclusion, a robust design is intrinsically linked to the value proposition of "Richard Gear." Effective design addresses the critical components of function, longevity, and aesthetics. Understanding the design principles behind "Richard Gear" is crucial for appraising its overall quality, reliability, and practical utility. This understanding transcends the specific product itself, extending to the broader principles of product development and their influence across various industries.

Innovation is inextricably linked to "Richard Gear," driving its development and shaping its impact. The pursuit of novel solutions and approaches is central to the evolution of this gear, impacting its functionality, durability, and overall utility. This exploration examines key facets of innovation within the context of "Richard Gear."

- Material Science and Technology

Advancements in materials science play a crucial role in "Richard Gear." The use of new, stronger, lighter, or more durable materials can enhance performance, reduce weight, and improve the gear's overall effectiveness. Examples range from specialized alloys for increased strength in industrial applications to lightweight composites for enhanced performance in sports equipment. By integrating these innovations, "Richard Gear" can be tailored for diverse applications, potentially extending its usability and efficiency.

- Design and Engineering Optimization

Innovative designs are central to "Richard Gear." Improvements in engineering principles allow for more effective load distribution, reduced friction, and increased structural integrity. This could involve the development of novel mechanisms or the refinement of existing designs to address specific challenges or enhance performance. For instance, incorporating aerodynamic principles into the design of sporting gear can reduce drag and improve speed. This highlights the interconnected nature of innovation in design and engineering optimization.

- Manufacturing Processes and Techniques

Innovations in manufacturing processes directly impact "Richard Gear." Automation, new production methods, and improved tooling can increase production speed, lower costs, and improve the quality of the final product. The application of 3D printing technologies, for instance, offers the potential for customization, intricate designs, and rapid prototyping. Consequently, new manufacturing processes can contribute to more accessible and cost-effective production of "Richard Gear."

- Addressing Specific Needs and Challenges

Innovation in "Richard Gear" often addresses specific market needs or challenges. This can include creating more user-friendly designs, addressing safety concerns, or improving the gear's adaptability to various environmental conditions. For instance, producing specialized gear for extreme environments or developing adaptable gear for diverse user profiles exemplifies a response to distinct needs and challenges, reflecting a dedication to creating effective and versatile solutions.

Consider the advancements in sensor technology and its integration into "Richard Gear." Embedding sensors into gear allows for real-time monitoring of performance parameters such as stress, temperature, and vibration. This data can be used to optimize performance, predict potential failures, and schedule maintenance proactively, ultimately extending the gear's lifespan and reducing downtime.

Another area of innovation lies in the development of self-healing materials. By incorporating microcapsules containing repair agents into the gear's structure, manufacturers can create gear that can automatically repair minor damage, extending its lifespan and reducing the need for costly repairs.

Furthermore, the application of artificial intelligence (AI) and machine learning (ML) is revolutionizing the design and operation of "Richard Gear." AI-powered design tools can automatically optimize gear geometry for specific performance requirements, while ML algorithms can analyze sensor data to predict potential failures and optimize maintenance schedules.

These facets collectively define "Richard Gear." Innovation, in all its forms, is critical to the gear's continued development. Understanding and applying these innovative principles enhances "Richard Gear" not only through its specific features but also through its capacity to adapt to changing requirements and advance the overall state-of-the-art within the field. This emphasis on constant improvement reflects the commitment to providing the most effective, reliable, and potentially transformative gear.

Manufacturing processes are integral to "Richard Gear." The quality, reliability, and ultimately, the value of the product are directly tied to the methods employed in its creation. Efficient and high-quality manufacturing ensures the gear meets its intended performance standards and durability requirements. Aligning manufacturing practices with design specifications is critical. This includes selecting appropriate materials, utilizing suitable tools and machinery, and adhering to stringent quality control measures. Deviations from these established protocols can result in compromised performance, reduced lifespan, and ultimately, a diminished value proposition for "Richard Gear."

Consider the example of high-precision components. Accurate machining and assembly, critical in their manufacture, are directly linked to the gear's precision and reliability. Failures in these stages can lead to performance issues or safety hazards. Similarly, the production of complex mechanisms involves intricate assembly processes. Thorough quality control at each stage, including inspection of components and final testing, is crucial to maintain consistency and minimize defects. Effective manufacturing of "Richard Gear" mandates a robust understanding of these technical aspects, ensuring the integrity of the product and its adherence to established performance criteria.

The adoption of lean manufacturing principles can significantly improve the efficiency and cost-effectiveness of "Richard Gear" production. By eliminating waste, streamlining processes, and empowering workers, lean manufacturing can reduce production time, lower costs, and improve quality.

Another key trend in manufacturing is the increasing use of automation and robotics. Automated assembly lines can perform repetitive tasks with greater speed and precision than human workers, reducing the risk of errors and improving overall efficiency. Robotics can also be used for hazardous tasks such as welding and painting, improving worker safety.

Furthermore, the rise of additive manufacturing, also known as 3D printing, is transforming the way "Richard Gear" is manufactured. Additive manufacturing allows for the creation of complex geometries and customized designs that would be impossible to produce using traditional manufacturing methods. This technology also enables rapid prototyping and on-demand production, reducing lead times and inventory costs.

Understanding the manufacturing processes behind "Richard Gear" offers several key insights. Firstly, it reveals the importance of meticulous planning and execution. Secondly, it underscores the interdependence of design, materials, and production. A sound understanding allows for a comprehensive evaluation of the gear's capabilities and limitations. This, in turn, enables informed decision-making regarding its suitability for various applications. Lastly, it highlights the critical link between manufacturing practices and the gear's overall cost-effectiveness. Optimized manufacturing processes contribute significantly to the affordability and accessibility of "Richard Gear." This connection underscores the multifaceted nature of "Richard Gear" and its dependence on a robust, efficient, and quality-focused manufacturing framework.

Quality is fundamental to "Richard Gear." The inherent reliability, durability, and performance of the gear directly correlate to its construction quality. Superior materials, precise manufacturing, and rigorous testing procedures are essential components for ensuring consistent quality. Defects in any of these areas can compromise the product's effectiveness, safety, and lifespan, impacting user experience and potentially leading to costly repairs or replacements. For instance, subpar materials in a piece of safety gear might lead to failure in critical situations. Conversely, the application of high-quality materials and precision manufacturing can significantly extend the product's operational life and enhance its performance, as demonstrated by the use of advanced alloys in high-performance automotive parts.

The importance of quality control during every stage of production cannot be overstated. From material selection and processing to assembly and final testing, each step must adhere to stringent standards. This rigorous approach prevents defects and ensures consistency in the product's attributes. This approach is particularly critical in industries demanding high reliability, such as aerospace and medical technology. If quality is compromised in these industries, the consequences can be catastrophic. An example is the meticulous testing and quality checks inherent in the production of aircraft components to guarantee air safety, highlighting the critical role quality plays in ensuring a products reliability.

The implementation of Statistical Process Control (SPC) is essential for ensuring consistent quality in "Richard Gear" production. SPC involves monitoring key process parameters and using statistical analysis to identify and correct deviations from established standards. This proactive approach helps prevent defects and ensures that the gear consistently meets its performance specifications.

Another key element of quality control is the use of non-destructive testing (NDT) methods. NDT techniques such as ultrasonic testing, radiography, and magnetic particle inspection can be used to detect internal defects in the gear without damaging it. This allows for the identification and removal of defective parts before they can cause problems in service.

Furthermore, the establishment of a robust quality management system (QMS) is crucial for ensuring consistent quality in "Richard Gear" production. A QMS provides a framework for documenting procedures, tracking performance, and implementing corrective actions. The ISO 9001 standard is a widely recognized QMS that provides a solid foundation for ensuring quality.

In summary, understanding the importance of quality within the framework of "Richard Gear" is crucial. It involves recognizing the direct relationship between quality and performance, the necessity of comprehensive quality control measures, and the significant impact of quality on the product's longevity and reliability. By adhering to these principles, "Richard Gear" can maintain a high standard of excellence, fostering trust and ensuring satisfaction among users. Ultimately, prioritizing quality is paramount in building a reputation for consistently superior products in any field, ensuring customer confidence and long-term success.

Durability is a defining characteristic of "Richard Gear." The inherent ability of the gear to withstand stress, wear, and tear over time is directly linked to its effectiveness and longevity. This resilience is critical for maintaining performance and safety in demanding conditions. Consideration of materials, design, and manufacturing processes are central to achieving and ensuring this crucial attribute. The long-term usability of the gear hinges on this enduring quality. Real-world examples of this principle include the use of high-strength alloys in critical components, such as structural supports in aerospace vehicles, or the durable, water-resistant design of gear employed in outdoor activities.

Durability is not simply a matter of material strength but also encompasses design robustness and the ability to withstand repeated use or exposure to harsh environments. The design of "Richard Gear" must anticipate potential stress points and incorporate mechanisms for mitigating wear and tear. For instance, in industrial machinery, robust seals and well-maintained lubrication systems are essential for extended equipment life. Similarly, in protective gear, the ability to withstand impacts and repeated abrasion is paramount. The interplay between the material's inherent characteristics and the design's engineering determine the gear's ultimate endurance. Practical significance stems from the reduction in replacement costs, maintenance requirements, and overall operational downtime. This translates into cost-effectiveness and increased operational efficiency.

The application of surface treatments such as coatings and hardening processes can significantly enhance the durability of "Richard Gear." Coatings can provide protection against corrosion, wear, and abrasion, while hardening processes can increase the gear's resistance to fatigue and impact.

Another key factor in durability is the proper selection of lubricants. Lubricants reduce friction and wear between moving parts, extending the gear's lifespan and improving its performance. The choice of lubricant should be based on the specific application and operating conditions.

Furthermore, regular maintenance and inspection are essential for ensuring the long-term durability of "Richard Gear." Maintenance activities such as lubrication, cleaning, and replacement of worn parts can prevent premature failure and extend the gear's lifespan. Regular inspections can identify potential problems before they become serious, allowing for timely repairs.

In conclusion, the durability of "Richard Gear" is a critical determinant of its value and utility. Achieving durability necessitates a thoughtful approach encompassing material selection, robust design, and meticulous manufacturing processes. Understanding the principles underlying durability is essential for optimizing performance, maximizing lifespan, and minimizing maintenance costs. This understanding is fundamental across various applications, from industrial machinery to personal protective equipment. Recognizing and prioritizing durability is key to achieving long-term reliability and overall success for "Richard Gear" and related endeavors.

Performance, in the context of "Richard Gear," represents the ability of the gear to effectively fulfill its intended function under various operating conditions. This encompasses not only the gear's capability but also its efficiency, robustness, and reliability. The precise nature of "performance" hinges on the specific application and expected operational parameters. Understanding this multifaceted dimension is crucial for evaluating and selecting the most suitable gear for a given task.

- Operational Efficiency

Operational efficiency within "Richard Gear" is measured by its ability to complete tasks with minimal expenditure of resources, be it time, energy, or materials. Examples range from the streamlined mechanisms in high-performance machinery reducing processing times to the ergonomic design of equipment maximizing user output. Improving operational efficiency directly translates into increased output and potentially lower operational costs. For "Richard Gear," this means delivering desired results with optimal resource utilization, whether it's minimizing energy consumption in a mechanical system or boosting productivity in a specialized tool.

- Load Capacity and Stress Tolerance

The load capacity and stress tolerance of "Richard Gear" denote its ability to withstand anticipated loads and stresses without failure or performance degradation. Practical applications include heavy-duty machinery designed for high loads, or protective gear capable of absorbing significant impacts. For "Richard Gear," understanding these parameters ensures the equipment can handle the anticipated workload and operate reliably under pressure without succumbing to damage or diminished effectiveness.

- Safety and Reliability

Safety and reliability are critical facets of "Richard Gear" performance. This involves the ability of the gear to operate safely and consistently under operational parameters without causing injury or failure. Examples include the robust construction of industrial safety gear and the high standards of reliability inherent in high-precision instrumentation. "Richard Gear" must meet stringent safety standards and maintain predictable performance in demanding situations, ensuring user well-being and equipment integrity.

- Adaptability and Versatility

Adaptability and versatility, often seen in advanced or specialized gear, demonstrate the gear's ability to perform functions across multiple applications. Examples include equipment adaptable for various terrains or adaptable toolsets capable of diverse operations. "Richard Gear" should ideally accommodate diverse use cases and environments without compromising effectiveness, reflecting adaptability to changing operational scenarios and promoting efficient use across various situations.

The use of advanced control systems can significantly enhance the performance of "Richard Gear." Control systems can monitor and adjust operating parameters in real-time, optimizing performance for specific conditions. For example, in a robotic system, a control system can adjust the speed and torque of the motors to achieve precise movements.

Another key factor in performance is the proper integration of "Richard Gear" into the overall system. The gear should be designed to work seamlessly with other components, ensuring optimal performance and reliability. For example, in an automotive drivetrain, the gear should be matched to the engine and transmission to achieve optimal acceleration and fuel efficiency.

Furthermore, regular testing and analysis are essential for validating and refining the performance characteristics of "Richard Gear." Testing can identify potential weaknesses and areas for improvement, allowing for iterative design and optimization. Analysis techniques such as finite element analysis (FEA) can be used to simulate the gear's performance under various loading conditions, providing valuable insights for design optimization.

Ultimately, the "performance" of "Richard Gear" transcends simple functionality. It encompasses a multitude of factors, from operational efficiency to safety, emphasizing the importance of a multifaceted approach when considering its capabilities. The design and implementation of "Richard Gear" should prioritize not just effectiveness, but also consideration of the conditions under which it will be utilized. Robust testing and analysis are imperative for validating and refining the gear's performance characteristics for optimal application.

Utility, in the context of "Richard Gear," signifies the gear's practical application and value. It encompasses the gear's ability to fulfill its intended purpose efficiently and effectively. The usefulness of "Richard Gear" hinges on this inherent utility. Cause and effect are evident: a high degree of utility necessitates well-defined design, robust materials, and precise manufacturing processes, which in turn impact the gear's broader application and potential returns. Effective utility also requires careful consideration of the specific needs and conditions under which the gear will be employed, ensuring optimal performance and longevity.

Practical applications underscore the importance of utility. For example, in industrial settings, the utility of "Richard Gear" might be defined by its ability to enhance productivity by minimizing downtime and maximizing efficiency. In contrast, specialized gear used for rescue or medical purposes might derive its utility from its ability to enable critical interventions under challenging circumstances. The selection of "Richard Gear" in any context hinges on its demonstrable utility, which is evaluated against specific operational needs and environmental factors. This utility-focused approach extends beyond mere functionality, emphasizing the gear's contribution to its specific intended application. Real-world examples of this are readily observable in various industries, highlighting the connection between utility and the effectiveness of "Richard Gear" in specific operational contexts.

The development of user-friendly interfaces and controls can significantly enhance the utility of "Richard Gear." Easy-to-use interfaces can reduce training time and improve user satisfaction. Intuitive controls can allow users to quickly and easily adjust operating parameters to meet specific needs.

Another key factor in utility is the gear's adaptability to different environments and applications. Versatile gear can be used in a variety of settings, reducing the need for specialized equipment. For example, a portable power generator that can operate on multiple fuel sources would be more versatile than a generator that can only operate on a single fuel source.

Furthermore, the provision of comprehensive support and training is essential for maximizing the utility of "Richard Gear." Support services can help users troubleshoot problems and maintain their equipment. Training programs can provide users with the knowledge and skills they need to operate the gear safely and effectively.

In essence, utility is not merely a desirable trait but a defining characteristic of "Richard Gear." Understanding its utility is crucial to evaluating the gear's overall value. A high level of utility translates into enhanced productivity, operational efficiency, and safety. The design and development of "Richard Gear" should prioritize utility, taking into account the specific requirements of diverse applications. Failure to address utility adequately leads to underperformance and limits the gear's potential contribution. Recognition of this connection between "Richard Gear" and its practical application is essential for informed decision-making and effective deployment of the gear.

This section addresses common inquiries regarding "Richard Gear," providing concise and informative answers to promote understanding and clarity. The following questions and responses are designed to offer practical insights into the characteristics, applications, and considerations surrounding "Richard Gear."

Question 1: What are the key features that distinguish "Richard Gear"?

The defining features of "Richard Gear" typically include superior durability, innovative design, high-performance capabilities, and the use of specialized materials. These attributes collectively contribute to the gear's suitability for diverse applications. Detailed information about specific materials and design elements are often available in accompanying product documentation.

Question 2: What industries or applications commonly utilize "Richard Gear"?

The utility of "Richard Gear" extends across diverse sectors, including heavy industry, aerospace, medical technology, and specialized manufacturing. The specific application of "Richard Gear" varies based on the gear's design and functional requirements. Detailed application notes are often found in product specifications or technical manuals.

Question 3: What are the material components used in the construction of "Richard Gear"?

Material selection for "Richard Gear" is often driven by the gear's intended function and operational conditions. Common materials include high-strength alloys, specialized polymers, or composites, chosen for their specific properties like strength, durability, or resistance to specific environmental factors. Further detail on material specifications can be found in the product's technical data sheets.

Question 4: How is the quality of "Richard Gear" ensured?

Quality assurance for "Richard Gear" involves rigorous testing and quality control measures at each stage of production. This ensures consistency in performance, durability, and safety standards. Detailed information on testing protocols and quality certifications is frequently available.

Question 5: Where can I find additional information and resources related to "Richard Gear"?

Further details on "Richard Gear," including specifications, technical manuals, and relevant case studies, are typically available on the manufacturer's website or through authorized distributors. Contacting the manufacturer directly is often the most efficient method for receiving up-to-date information.

Understanding these frequently asked questions provides a foundational knowledge base for comprehending "Richard Gear." Consistent evaluation of the stated features and properties will contribute to effective application and usage of the gear. Further detailed product documentation is recommended for a comprehensive understanding.

The subsequent section will delve into specific case studies showcasing the use of "Richard Gear."

This exploration of "Richard Gear" has highlighted the multifaceted nature of the product. The analysis demonstrates that the gear's value proposition is derived from a complex interplay of design elements, material choices, manufacturing processes, and adherence to stringent quality standards. Key aspects examined include design innovation, the selection of durable and high-performance materials, efficient manufacturing, and unwavering commitment to quality control throughout production. The article further emphasizes the importance of understanding these interrelated factors to effectively leverage "Richard Gear" across various applications. By examining operational efficiency, load capacity, and safety considerations, the analysis underscores the comprehensive nature of "Richard Gear" and its suitability for diverse operational contexts. The overall utility, performance, and durability of the gear are directly linked to the quality of its underlying design, manufacturing, and testing principles. Ultimately, "Richard Gear" offers a robust and reliable solution for demanding situations.

In conclusion, "Richard Gear" represents a culmination of meticulous engineering and dedication to high standards. Recognizing the intricate balance between functionality, performance, and durability is critical for its successful deployment and maximizes its inherent value. Future advancements in material science and manufacturing technology will undoubtedly shape the evolution of "Richard Gear," possibly leading to enhanced performance characteristics and wider applications. The enduring importance of quality and reliability in modern applications remains paramount, and "Richard Gear," as highlighted here, stands as a testament to these enduring values.

- Zefoy Is This Website Builder Right For You 2024 Review

- Will Estes The Untold Story Facts About His Career

Richard Gere Chapters Site

Richard Gere ArryaAriette

Richard Gear HD wallpaper Wallpaper Flare