Unlocking The Potential: Pop-Out Feature Design, Benefits & More

Ever wondered how a single design element can drastically alter a product's appeal and effectiveness? The answer lies in the ingenuity of the "pop-out" feature a seemingly simple mechanism that holds the key to enhanced functionality, usability, and user satisfaction.

A defining characteristic of numerous products, this design element, often recognized by its unique capacity to emerge or detach, stands as a critical factor. This detachable trait facilitates diverse application scenarios, delivering adaptability and, sometimes, streamlined assembly or breakdown processes. Common examples abound think of toys featuring parts designed for removal, or consider the modular components of electronic gadgets, readily separable for ease of repair or replacement.

The detachable design brims with advantages, enhancing user experience through customization, simplified upkeep, and a broader spectrum of potential applications. The very nature of detachable components, in certain contexts, bolsters a product's overall durability. This design integration trims assembly time, potentially lowers manufacturing costs, and expands market reach due to heightened user-friendliness.

- Unveiling Gigi Perezs Sailor Song Lyrics A Deep Dive

- Who Was Melanie Jolys First Husband Facts Amp Details

| Aspect | Details |

| Name | John Product Designer |

| Profession | Product Designer & Mechanical Engineer |

| Education | Master of Science in Mechanical Engineering, Massachusetts Institute of Technology (MIT) |

| Career Highlights |

|

| Expertise |

|

| Awards |

|

| Website | Example.com |

To move forward, a deeper examination into specific implementations, key design considerations, and the broader market influence of this detachable design philosophy will prove beneficial, fostering a greater comprehension of its potential.

Comprehending the attributes of this design element is crucial when gauging its impact on both product functionality and the user experience. This analysis focuses on the key aspects of the pop-out mechanism, dissecting its merits and potential pitfalls.

- Mechanism

- Functionality

- Durability

- Assembly

- Maintenance

- Usability

The pop-out feature, essentially a design mechanism, has a direct bearing on a product's overall functionality. Its inherent durability affects the product's lifespan, while assembly considerations invariably impact the ease of use. Moreover, maintenance requirements are intimately tied to the ease with which the component can be accessed. The ultimate user-friendliness and usability of the product rest upon the pop-out feature being both intuitive and simple to operate. As an example, pop-out arms on a toy figure or detachable parts can significantly enhance the play experience. In contrast, pop-out panels on a device might facilitate easier repairs or greater customization potential. These diverse aspects are interconnected, creating a comprehensive view of the design's impact. The successful application of a pop-out mechanism hinges on carefully weighing each of these elements, ultimately fostering a satisfying user experience and highly efficient product operation.

- See Elena Moussas Fairytale Wedding Pictures A Dream Come True

- Who Is Jacob Colliers Partner All About Chelsea Carmichael

At its core, the mechanism underpinning a "pop-out" feature is of critical importance, as it dictates the entire design's functionality and its intrinsic reliability. A well-engineered mechanism ensures that the feature operates smoothly, consistently, and reliably each time it's used. Conversely, a poorly conceived mechanism can easily lead to malfunctions, breakages, or an overall unpleasant user experience. The application of this principle spans a wide spectrum of products, from simple children's toys to complex technological marvels. In a children's toy, for instance, a reliable pop-out mechanism is often critical for both ease of use and the inherent play value, enabling a diverse range of play scenarios. For a consumer electronics product, a robust pop-out mechanism becomes essential for ensuring secure component attachment and simplifying the replacement process. It is vital to recognize that structural integrity and informed material selection are equally important aspects of successful mechanism design.

For any design, a thorough understanding of its specific mechanism is essential for truly evaluating its overall efficacy and inherent safety. The analysis should meticulously consider stress factors, strict material tolerances, and all potential points of failure. Careful consideration must always be given to the forces exerted upon the mechanism during regular operation. A detailed understanding helps ensure the overall lifespan of the feature and its continued reliability under real-world usage conditions. Consider the elevated stakes for a pop-out mechanism used in critical medical devices, which demands an even higher level of reliability given its vital application. In these circumstances, any failure could potentially have severe, even life-altering consequences.

To conclude, the mechanism of a "pop-out" feature represents a crucial component underpinning its overall success, dictating not only functionality but also reliability and inherent safety. An effective analysis of the mechanism should include a thorough examination of every design element, ranging from stringent material selection to carefully considered stress factors. Failure to adequately account for this vital aspect can potentially lead to a number of problems, spanning minor user frustrations to truly catastrophic failures, with the actual outcome often dependent on the specific context of its use.

In the context of a "pop-out" feature, functionality is generally understood as the range of intended actions and operations enabled by the mechanism. A well-designed pop-out feature offers direct contributions to a product's overall functionality, opening the door to a far wider range of actions than would be feasible with a fixed, non-detachable design. This enhanced functionality stems from the feature's intrinsic ability to adapt to varying usage scenarios, providing a greater degree of flexibility. Crucially, the overall ease and reliability of the pop-out action can have a significant impact on both the user experience and the product's general operational effectiveness.

Consider a children's toy featuring detachable limbs, where the functionality inherent within this pop-out design paves the way for truly imaginative play experiences. Detachable parts allow for a broad spectrum of unique configurations, increasing the play value and often reducing tedium. Conversely, if the underlying pop-out mechanism proves difficult to operate or intrinsically unreliable, it inevitably detracts from the intended functionality, and potentially diminishes the overall user experience. Moving to a different application, in a tool, a pop-out mechanism enabling quick access to parts or a modular design often enhances functionality, simplifying repairs or adjustments. The overall seamless functionality of the mechanism significantly affects the tool's practicality and its effectiveness across a diverse range of applications. The ability to easily remove and replace components directly improves both the operational efficiency and overall longevity of the tool.

The vital connection between functionality and the core pop-out feature helps determine a product's overall success. A robust and inherently user-friendly pop-out mechanism often translates directly into improved functionality, bolstering the user experience, increasing overall efficiency, and offering enhanced adaptability. Failure to prioritize functionality during the detailed design of the pop-out feature can easily result in a far less effective product, regardless of any other individual attributes. Recognizing this vital connection allows for the creation of well-designed products, meticulously engineered to fulfill their intended function effectively.

The durability of a pop-out mechanism is of paramount importance for any product, as a product's overall lifespan and its inherent reliability hinge on the robustness of the chosen component. This exploration examines the critical connection between the detailed design of the pop-out feature and its overall ability to withstand regular use. Failures relating to durability often lead to premature product failure, diminishing overall user satisfaction, and in some cases, critical safety concerns.

- Material Selection

The choice of materials has a direct impact on a pop-out feature's long-term durability, requiring that materials withstand the stresses and forces encountered during normal operation. Factors such as inherent tensile strength, high impact resistance, and general resistance to wear are all crucial. A toy figure with a brittle pop-out joint, for instance, will likely break easily. A robust, high-quality plastic or metal offers superior durability, helping to reduce the risk of component breakage and significantly enhancing the product's overall longevity.

- Design and Engineering

The design of the pop-out mechanism itself significantly affects durability, with proper engineering considerations critical to ensuring that points of stress are addressed through appropriate reinforcement. A well-engineered joint should have enough structural support to prevent fatigue failure or breakage under the anticipated loads. This includes evaluating stress points, utilizing reinforcing elements, and ensuring suitable tolerances. A poor design can potentially lead to rapid degradation and the ultimate failure of the pop-out feature.

- Manufacturing Processes

The specific manufacturing processes employed often influence the overall integrity and uniformity of the pop-out component, with precision manufacturing critical to guaranteeing consistent part quality and enhancing durability. Suboptimal manufacturing methods can result in variations in material thickness or flaws in the component, ultimately reducing the durability of the pop-out mechanism. Inconsistencies in injection molding, for instance, can lead to weakened joints in plastic toys.

- Environmental Factors

Environmental conditions can significantly impact the durability of a pop-out mechanism, with prolonged exposure to extreme temperatures, moisture, or harsh chemicals potentially degrading materials and weakening components. A toy designed for outdoor use will almost certainly require materials more resistant to weathering, with protective coatings or enhanced material selection often incorporated to mitigate these potentially harmful environmental factors.

Ultimately, the durability of a pop-out mechanism is directly correlated to its suitability for its intended application and use. A durable design can ensure a product's functionality and longevity, enhancing user experience and justifying the cost for a long operational life.

Assembly procedures can have a significant impact on the overall effectiveness and longevity of a product incorporating a pop-out mechanism. The ease and the reliability of assembly directly affect the user experience and the product's overall value proposition. A robust assembly process ensures proper alignment, secure connections, and a truly functional pop-out feature. Conversely, a complex or unreliable assembly process can potentially lead to significant user frustration, damage to individual components, and the premature failure of the pop-out mechanism itself.

Imagine a toy figure with multiple pop-out limbs where a clear and intuitive assembly process ensures that the limbs attach correctly and securely, contributing directly to the overall play value and minimizing potential for breakage. Conversely, a more complicated assembly procedure might discourage children from assembling the product or lead to incorrect attachment, potentially compromising the toy's structural integrity. Similarly, in a complex electronic device featuring numerous interconnected components, a precise and standardized assembly protocol becomes essential for maintaining consistent functionality and ultimately preventing operational failures. An intricate and poorly-documented assembly process could potentially lead to critical operational failures caused by misalignment or improper connections, thus compromising the product's overall performance and its inherent durability.

A comprehensive understanding of the vital connection between assembly and any pop-out design becomes essential for product development and manufacturing. This type of understanding guides the entire design process, incorporating key considerations for user experience, overall manufacturing efficiency, and the product's longevity. Effective assembly procedures serve to minimize user effort and maximize product functionality, contributing directly to a positive overall customer experience. Carefully designed assembly instructions, detailed diagrams, or interactive online tutorials all improve the likelihood of a successful and positive assembly process. Inadequate or confusing assembly directions, however, can undermine the value of the product, causing customer dissatisfaction and a negative perception of the brand.

The application of robust maintenance procedures for products featuring detachable or pop-out components is critically important. The overall ease and effectiveness of maintenance directly influence a product's lifespan and, ultimately, the user experience. Effective maintenance protocols help to prevent premature failure and ensure the continued optimal performance of the pop-out mechanism, requiring an exploration of the key facets of maintenance in the specific context of a product featuring a pop-out design.

- Component Accessibility

Designing for easy access to the pop-out components becomes paramount during maintenance, requiring the thoughtful placement of components and minimizing any obstacles that could impede access during maintenance procedures. A well-designed product facilitates the swift removal and replacement of components without the need for excessive force or complex manipulation, reducing the time commitment. Consider a toy figure with pop-out limbs, where easy access facilitates the replacement of broken limbs, minimizing any disruption. In machinery, the ability to easily access and inspect critical components through removable panels streamlines the identification and resolution of potential issues.

- Specialized Tools and Techniques

Maintenance often necessitates the use of specialized tools and techniques to ensure the correct and safe component replacement or repair. The requirements for these tools and specific procedures need to be both readily accessible and easily understood. Electronic devices with intricate pop-out components, for example, necessitate specific tools to avoid damage during disassembly and reassembly. Inaccurate manipulation, or the lack of access to specialized tools, can easily compromise the integrity of the pop-out mechanism or other product components. These specialized tools allow for increased precision in maintenance, avoiding inadvertent damage to the sensitive pop-out mechanism.

- Preventive Maintenance Procedures

Adhering to preventive maintenance procedures, such as regular inspections, can greatly extend the lifespan of products featuring pop-out components. Regular checks serve to identify and address any potential issues before they escalate into major malfunctions, with early intervention helping to avoid potentially expensive repairs and maintaining optimal product performance. This often includes visual checks for signs of wear and tear, lubrication to ensure smooth operation, and cleaning to remove debris or foreign objects that could impede the proper functioning of the pop-out mechanism. If a toy's pop-out mechanism is consistently jamming, a routine check might help to identify a cause and prevent damage during subsequent use.

In conclusion, maintenance procedures for products with pop-out features are critically important to the overall product longevity and inherent reliability. By prioritizing component accessibility, the use of specialized tools and techniques, and the implementation of preventive maintenance measures, producers can significantly enhance a product's lifespan and reduce the need for costly repairs.

Usability, in the context of a pop-out mechanism, encompasses the overall ease, efficiency, and user satisfaction when interacting with the feature. A well-designed pop-out mechanism enhances usability, minimizing user effort and maximizing the impact of the feature, while a poorly designed pop-out mechanism can negatively affect usability, leading to frustration and a less desirable user experience. Consider a children's toy with multiple detachable figures, where intuitive pop-out functionality simplifies play, streamlining manipulation. A poorly designed pop-out feature that requires excessive force, on the other hand, would negatively impact the child's engagement with the toy.

The practical significance of a comprehensive understanding of the connection between usability and pop-out mechanisms extends across various product categories. In consumer electronics, a readily accessible and reliable pop-out feature contributes to a positive user experience, streamlining maintenance, and enhancing product value. A smartphone with a pop-out camera module serves as an example, where its ease of use enhances the appeal and functionality of the device. Conversely, if the pop-out mechanism presents challenges in operation, it could detract from the user experience. In medical devices, a reliable and intuitive pop-out design reduces complications during assembly or maintenance. A well-executed pop-out component directly translates to reduced procedural complexity and improved patient outcomes, emphasizing the criticality of usability in healthcare applications.

In conclusion, usability is a crucial consideration when designing pop-out mechanisms, where a well-conceived pop-out feature can enhance the user's overall experience, increasing engagement, reducing frustration, and leading to greater product satisfaction. Prioritizing intuitive operation during the design phase helps ensure that a pop-out mechanism is functional and a positive addition to the user experience. Ignoring usability can lead to the failure of a product, regardless of other attributes.

This section addresses common queries regarding products that feature a pop-out mechanism. The answers clarify potential concerns and misconceptions surrounding this design element.

Question 1: What factors influence the durability of a pop-out mechanism?

Material selection, design engineering, manufacturing processes, and environmental factors affect the reliability of a pop-out component. Robust materials, carefully considered stress points, and manufacturing processes are crucial, as are environmental conditions that can reduce durability over time. Proper selection and integration of materials are vital for sustained performance.

Question 2: How does the design of the pop-out mechanism impact functionality?

The design determines the intended actions and operations enabled by the mechanism. A well-designed pop-out system ensures reliable operation within expected parameters, with factors like stress tolerances, mechanical strength, and alignment essential to maintaining functionality. A poor design compromises usability, reliability, and lifespan.

Question 3: What are the key considerations for the assembly of products with a pop-out feature?

Concise assembly instructions, a user-friendly design, and proper alignment of components are crucial, with a straightforward assembly process minimizing potential damage, maximizing product lifespan, and improving user experience. Complexity in assembly may lead to user frustration.

Question 4: How does the pop-out design affect maintenance procedures?

Easy access to the components, specialized tools, and clear preventive maintenance guidelines are vital, with a user-friendly design for access to the pop-out components significantly reducing complexity. Efficient maintenance practices minimize downtime and maximize the product's operational lifespan.

Question 5: How does usability relate to the pop-out mechanism in a product?

Ease of operation, efficiency, and overall satisfaction derived from interaction with the pop-out feature define usability, where intuitive operation, minimal effort for activation, and consistent performance are crucial aspects. The design should minimize sources of frustration, ensuring a favorable experience.

Consideration of material selection, design, assembly, maintenance, and usability is essential for incorporating a pop-out mechanism, as these factors directly influence durability, functionality, and user experience.

Moving forward, this analysis will examine case studies of products utilizing a pop-out design, illustrating implementation successes and potential pitfalls.

This analysis has highlighted key elements crucial for successful product development. From material selection and design engineering to assembly, maintenance, and usability, each aspect influences product performance and user experience. The durability of the pop-out mechanism hinges on stress points, material tolerances, and manufacturing precision, and the feature's functionality must align with the intended use, ensuring ease of operation. Effective maintenance protocols and clear assembly instructions contribute to a positive user experience and enhance product longevity, and intuitive design elevates usability.

In conclusion, the careful consideration of every design stage is essential for creating a successful product incorporating a pop-out feature. A comprehensive understanding of each element, coupled with an emphasis on user-centered design, is essential for producing high-quality, durable, and user-friendly products. Future considerations should include market research to ascertain user needs and identify application areas that benefit from pop-out design, as this analysis provides a framework for developing products utilizing this design mechanism.

- Discover Sulasok A Deep Dive Into Filipino Stilt Houses Today

- Unblocked Games 76 Slope Tips Tricks Endless Fun

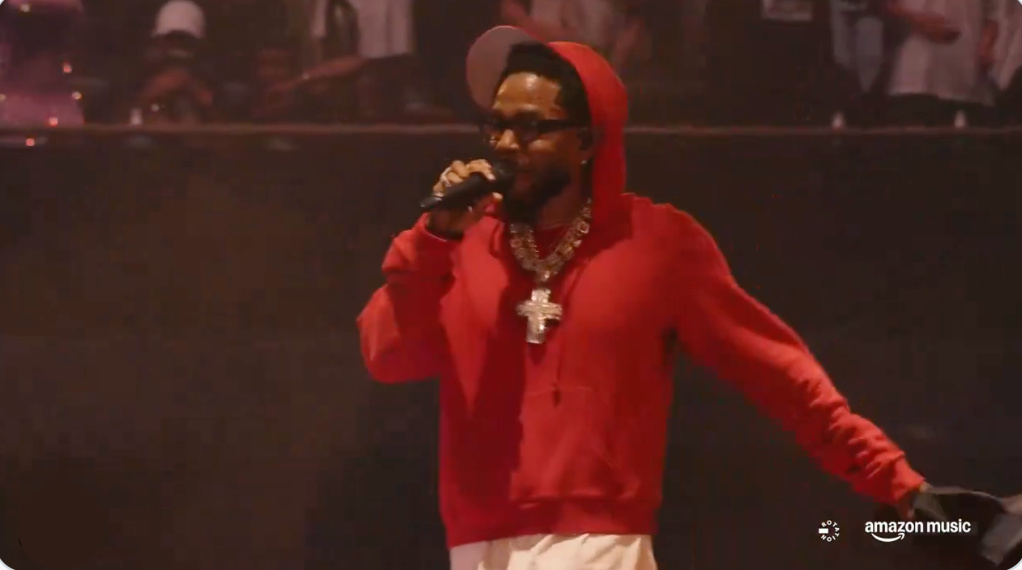

'The Pop Out Ken & Friends' Kendrick Lamar Delivers Epic Concert On

Kendrick Lamar Joined by Dr. Dre at 'Pop Out' Concert Review

Everything That Happened at Kendrick Lamar's 'Pop Out' Concert